Engineering Plastics

Engineering plastics need to be strong, light and show exceptional performance, strength or heat resistance as well as demonstrate long-term reliability and resistance to fatigue. Aerospace Materials offers a large choice of specifications and forms of engineering plastics to the aerospace industry. With over 25 years of experience Aerospace Materials, uses in depth knowledge and experience, to help you in select the correct material and grade for your aerospace needs.

Our comprehensive range of materials for the manufacture, modification and maintenance of aviation vehicles come from approved suppliers and are fully traceable through our quality control system. If you have specific requirements or do not see what you're looking for below, please contact a member of the Aerospace Materials sales team who will be able to help you further.

Kapton®

Kapton® products exhibit a unique combination of electrical, thermal, chemical and mechanical properties that withstand extreme temperature and vibration under the harshest of conditions and in the most demanding environments. For over 45 years, Kapton® polyimide films have set the industry standard for high performance, reliability and durability.

Its excellent chemical resistance, (there being no known organic solvents) and reliability over a wide temperature range make it ideal for use throughout the aerospace industry in printed circuits, transformers and capacitors. Available in shim, sheet and tube.

- Kapton Type HN

- Kapton Type VN (Superior dimensional stability)

- Kapton Type FN (Teflon Coated)

Teflon®

Teflon® fluropolymer is a family of plastics used in a wide range of industrial applications from electrical insulation to moldings and non-stick coatings. Products made with fluoroplastic resins have exceptional resistance to high temperatures, chemical reaction, corrosion and stress cracking. It is these properties of Teflon® which make it the preferred solution for a host of industrial applications and different processing techniques. Available in film, tube, rod, coatings and powder.

Phenolic Resin

Phenolic sheet is a hard dense material made by applying heat and pressure to layers of paper, cotton or glass cloth impregnated with synthetic resin. When heat and pressure are applied to the layers, a chemical reaction (polymerization) occurs and transforms the layers into a high pressure thermosetting industrial laminated plastic. Available in sheets - thicknesses from 0.005” to 2.0”

- Paper Reinforced (MIL-I-24768 PBG)

- Cotton Reinforced (MIL-I-24768 TYPE FBM & MIL-I-24768 TYPE FBG)

- Linen Reinforced (MIL-I-24768 TYPE FBI & MIL-I-24768 TYPE FEI)

- Nylon Reinforced (MIL-I-24768 TYPE NPG)

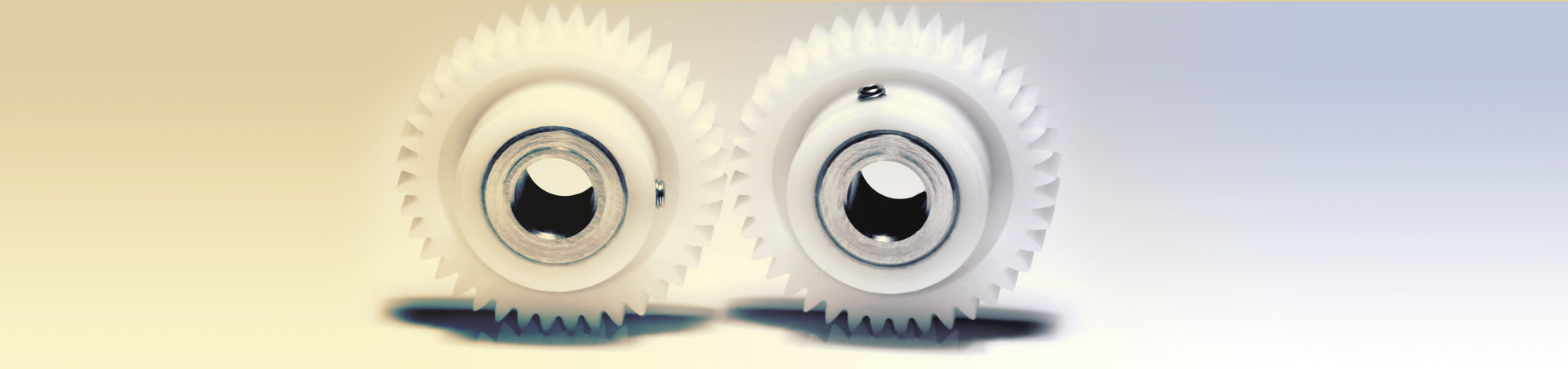

Delrin® Acetal Resin

Dupont Delrin acetal polyoxymethelene resins are highly versatile engineering plastics that bridge the gap between metals and plastics. They offer high strength, resistance to impact and good insulation. A wide range of specifications and forms of this product are available please contact a member of our sales team for more details.

*Teflon®, Kapton® and Delrin® are trademarks of the Dupont Corporation